Advantages of PVC pipe production line

Published on:

2020-07-29

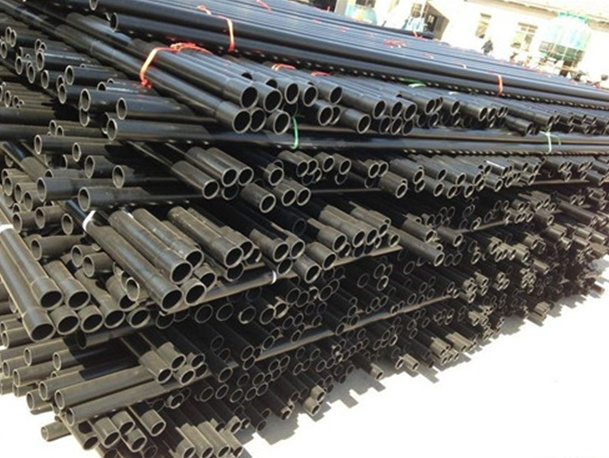

PVC material is one of the plastic products with high production value in the world. It is cheap and widely used. PVC resin is white or light yellow powder. According to different uses, it can participate in different additives, and PVC plastics can exhibit different physical and mechanical functions

PVC material is one of the plastic products with high production value in the world. It is cheap and widely used. PVC resin is white or light yellow powder. According to different uses, it can participate in different additives, and PVC plastics can exhibit different physical and mechanical functions. Participate in an appropriate amount of plasticizer in the polyvinyl chloride resin to make a variety of hard, soft and transparent products. PVC can be divided into soft PVC and hard PVC. Hard PVC accounts for about 2/3 of the total, and soft PVC accounts for 1/3. Soft PVC is generally used for floors, ceilings and leather surfaces. Polyvinyl chloride hard boards are widely used in the chemical industry to make fabrics for various storage tanks, corrugated boards for buildings, door and window structures, wall decorations and other construction materials.

The PVC pipe production line has outstanding air permeability and can effectively prevent static electricity. The main ingredient is polyethylene, which is a new type of packaging material. During the production process, polyethylene produces countless bubbles. Suddenly, general materials are fragile, It is easy to deform and other shortcomings, can produce outstanding resistance, and play an outstanding cushioning effect on the packaging.

PVC pipe production line is not deficient in the transportation industry. Its existence helps us protect our belongings effectively and is an important helper in our lives.

The PVC pipe production line is not very unfamiliar to many people. It is widely used in our days. The effect of the PVC pipe production line is in electronic appliances, computers, audio, lighting, various exquisite crafts, toys, and melons. As a protective material, its value is deeply manifested in the transportation process.

Production process: material additives manufacturing→mixing→transporting and loading→forced feeding→conical twin-screw extruder→extrusion die→sizing sleeve→spraying vacuum setting box→soaking cooling water tank→ink printing machine→track traction Machine → lift the knife to cut the machine → pipe stacking rack → product inspection and packaging.

TAG:

PREVIOUS:

NEXT:

Related Posts