What are the steps of hot melt welding of PVC pipes for mining

Published on:

2020-07-29

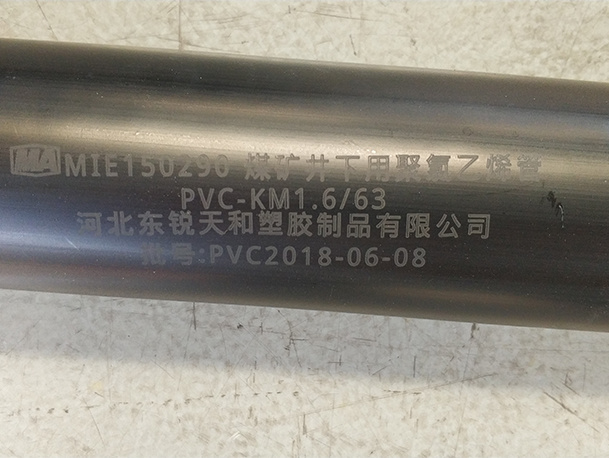

Mine PVC pipes overcome the shortcomings of the difficulty of hot-melt welding of pure plastic mine PVC pipes. Flanges and quick connector numbers can be used to connect with the original underground steel pipes and valves according to requirements, which have strong interchangeability. This page specifically introduces the common sense of the hot melt welding process and matters.

Mine PVC pipes overcome the shortcomings of the difficulty of hot-melt welding of pure plastic mine PVC pipes. Flanges and quick connector numbers can be used to connect with the original underground steel pipes and valves according to requirements, which have strong interchangeability. This page specifically introduces the common sense of the hot melt welding process and matters.

First. Data preparation

Turn on the power of each part of the welding machine. It is necessary to use 220V, 50Hz alternating current, and the power supply should have a grounding wire; together, it should be ensured that the surface of the heating plate is clean and free of scratches;

Second, hurry up

Place the mine PVC pipe or pipe fittings in a flat position, and place them on the butting machine, leaving enough cutting allowance of 10-20mm; select suitable slip fixtures according to the pipes and pipe fittings to be welded, clamp the pipes, and prepare for cutting preparation;

Three, cutting

Cutting the welded pipe section, the end surface impurities and oxide layer of the pipe fittings, to ensure that the two butt joint ends are flat, bright and free of impurities;

Four, centering

Check the concentricity of the PE pipe. When the gap between the two ends and the amount of misalignment cannot meet the requirements, the weldment to be welded should be clamped from the beginning, milled, and the next step can be performed after it is qualified;

Five, heating

Check whether the temperature of the heating plate is suitable for 210℃~230℃, and the melting length of both sides should be 1~2mm;

Six, switch

1. Remove the heating plate, quickly let the two hot melt end faces adhere and pressurize. In order to ensure the quality of the melting and jointing of PVC pipes for mining, the shorter the switching period, the better;

2. After reaching the end of heat, quickly turn over the tool and remove the heating plate. When taking the heating plate, avoid collision with the molten end surface; if it has occurred, start the entire welding process from the beginning after the molten end surface has cooled;

Seven, fusion docking:

The key to welding, the butt joint process should always be carried out under melting pressure, and the curling width should be 1~2mm;

Eight. Cooling: Keep the docking pressure unchanged, and let the interface cool down slowly. The cooling time is based on the stiffness of the curling by the hand and no heat;

Nine, the docking is over

After reaching the cooling time, the pressure is reduced to zero, the clamp is opened, the welded pipe (pipe fitting) is removed, the butt joint machine is removed, and the next interface connection is prepared from the beginning.

TAG:

PREVIOUS:

NEXT:

Related Posts